The last few weeks have seen a sudden surge of activity in the studio after many months of uncertainty. This little black hare can now reveal that she hasn’t been sure up until now whether or not The Harebrained Press could continue in the face of many practical and technical difficulties.

Even after the stroke of good fortune in finding my (old) new printing press, Rinaldo, I was unsure as to whether he’d be up to the job. I’ve become accustomed to working on two highly-engineered presses with automatic inking systems, so going back to inking by hand filled me with apprehension.

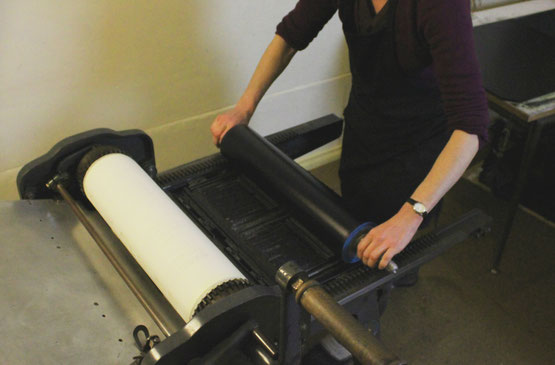

Letterpress printing is a craft characterised by its technical nature and by the idiosyncratic union of ink, cast metal, and (in my case) cotton paper. However, these qualities can turn against you and become an inky mess if your operation isn’t calibrated properly. The first thing I needed was a good, solid inking roller to serve as the heart of the press. This roller had to be a specific length, and have a diameter and rubber consistency to work well with metal type. Thanks to Stephen Twohig at Fitzroy Etching Presses, my spindle roller is perfect and was completed in good time.

After over sixty hours of solid work in the studio, running into one problem after another and adjusting my process accordingly, I’m relieved to announce that my first printing run is done and I now know that Rinaldo will get me over the finish line with some good-quality, though hard-won printing. And, I’ll be fit too, as my new roller weighs over four kilos! Watch my video to see the operation unfold.

Write a comment